Spanish company PAL Robotics has taken delivery recently of a Haas CNC Mini Mill, which it will use to develop and make various critical parts for its latest design of humanoid, service robots.

Humanoid robot

PAL Robotics is based on the third floor of an office building in central Barcelona, a few minutes by car from the city’s busy and famous Las Ramblas promenade.

The company, run by Italian CEO Francesco Ferro, is building a reputation for its cutting-edge, innovative humanoid robots used in service applications such as hotels and shops, as well as in warehouses and supermarkets. To the layman, these are human-sized robots that look, move and sound like automatons from science fiction movies. But, they’re not fantasy. They are in fact advanced, highly engineered creations, designed in-house by a group of talented engineers.

Up until now, all of the metal parts used to make a robot have been sourced from various external subcontractors and suppliers in Spain and overseas.

“Using subcontractors has its advantages, but also has some serious limitations,” says Mr. Ferro, “especially during the prototype and development phase of a new design. For example, a complex assembly such as a hand includes very precise metal parts. We make many changes and improvements with an iteration of the design process. Sourcing the parts externally can slow down the prototype process considerably.

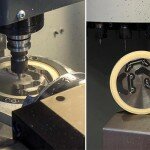

“The Haas Mini Mill is the perfect size and power for our workshop. As it’s our first CNC machine, it’s also important that it’s easy to programme and use and that it’s reliable. I didn’t know much about Haas before we bought it, but when I started to investigate, I discovered very good things. The price and performance were exactly what we were looking for.”

The compact and popular Haas Mini Mill comes with a 5.6kW, 6000rpm, 40-taper spindle as standard, giving it plenty of performance for cutting steel or Al alloy. Its worktable of 914mm x 305mm is the perfect size for small to medium sized parts and can easily accommodate a Haas rotary table for multi-axis machining. Maximum load on the table is 227kg!

Shown in the accompanying photograph is REEM: C, the third version of a full-sized, humanoid robot. With a battery life up to 8-hours, PAL says ‘she’ can be used, for example, as a receptionist at an event or trade show, can entertain and compliment guests, provide dynamic information and even make presentations and speeches in many, different languages.

“REEM: C is a huge improvement on its two predecessors,” says Mr. Ferro. “Now that we have the Haas CNC Mini Mill, we’re looking forward to making parts much more quickly, so we can push forward with our R&D and build an even more advanced REEM. Come back and see us in 6-months! I think you’ll be impressed.”

Source HAAS Source Pal Robotics

Smiles Better — Haas Customer Success Story

Smiles Better — Haas Customer Success Story

This is how Haas makes 5-axis machining affordable

This is how Haas makes 5-axis machining affordable

Haas makes 5-axis machining affordable for smaller companies

Haas makes 5-axis machining affordable for smaller companies

Star-Turn — Haas Customer Success Story

Star-Turn — Haas Customer Success Story

The strong and silent type

The strong and silent type