Ulsan Metropolitan City, South Korea’s industrial center, has announced a collaboration with Materialise to drive business growth for the local manufacturing industry by leveraging the transformational power of additive manufacturing. As part of this agreement, Materialise will engage in co-creation campaigns with local manufacturing companies to identify opportunities to optimize the manufacturing process.

Over the past several decades South Korea has positioned itself as a leading manufacturing economy. Ulsan Metropolitan City, South Korea’s seventh-largest metropolis, is at the heart of this manufacturing industry, hosting some of the world’s largest automobile assembly plants, shipyards and oil refineries. In order to reinforce its competitive position, the Ulsan Metropolitan City government is presenting a roadmap of growth that will focus on the convergence of digital technologies and manufacturing, leading to smarter and better connected production processes and factories.

Additive manufacturing will play a key role in this digital, data-based transformation and that is why the Ulsan Metropolitan City government is teaming up with Materialise. With almost three decades of 3D printing experience, Materialise is a pioneer and a leading provider of Additive Manufacturing software and services for the medical and industrial markets.

“Additive Manufacturing is a transformational technology that has the potential to create fundamental changes in the manufacturing process”, says Johan Pauwels, Executive Vice President at Materialise. “With major improvements in speed, quality and materials, Additive Manufacturing is quickly positioning itself as a complementary or alternative manufacturing technology when solving specific manufacturing challenges. By delivering weight, performance and cost advantages it allows for fundamental design optimizations and functional improvements, such as lighter designs, that are impossible to create with standard manufacturing technologies.”

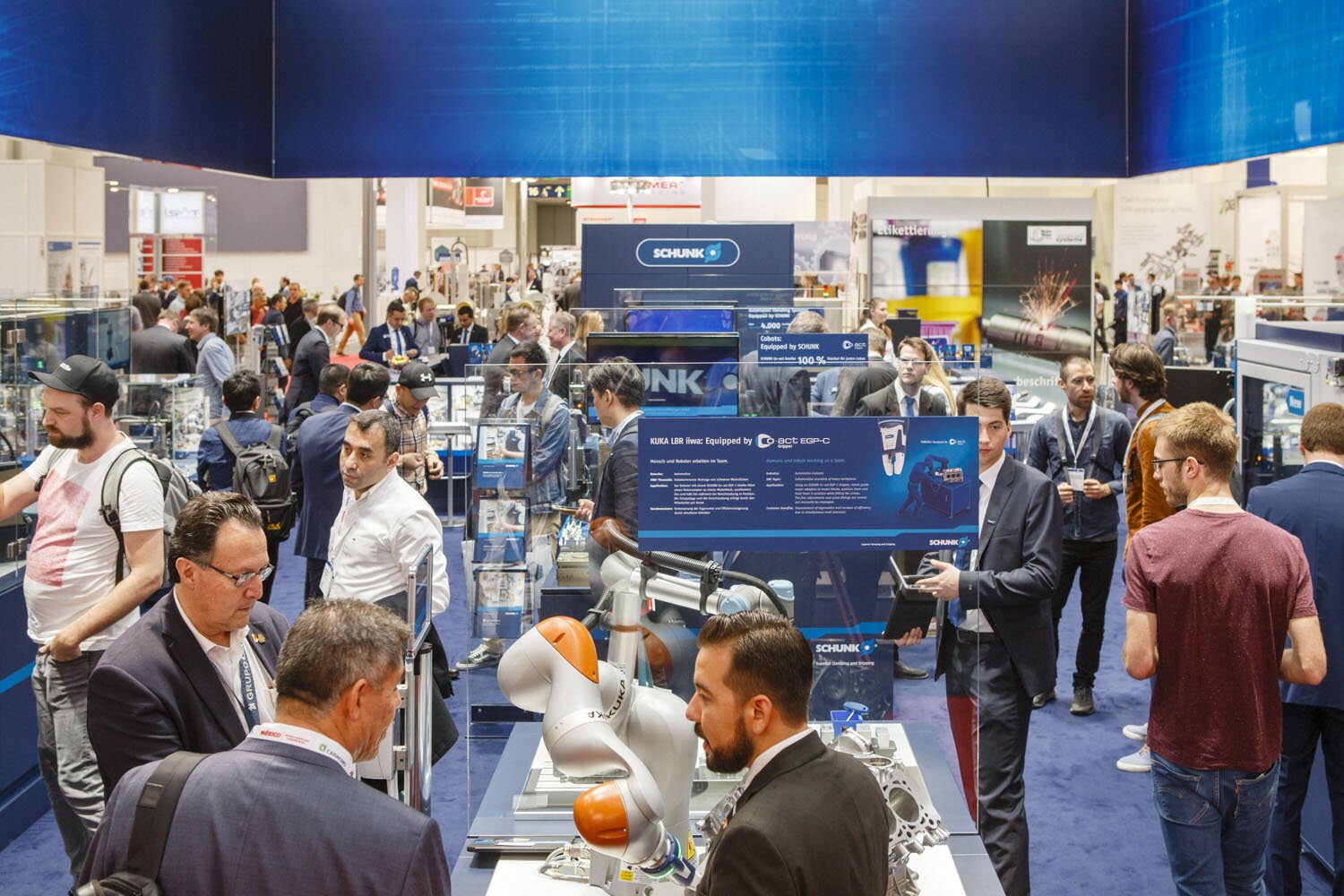

Innovation through co-creation

As part of the agreement, Materialise will help manufacturing companies in Ulsan Metropolitan City to develop applications that generate business growth by enabling significant manufacturing process optimizations. This will happen through intensive co-creation projects, where Materialise will combine its 3D printing expertise with the manufacturing company’s industry and product knowledge and manufacturing experience. During this process, both companies will look for elements in the production process that can benefit from the design optimizations and manufacturing flexibility provided by Additive Manufacturing. The results of these co-creation projects will be presented at the Ulsan 3D Printing Tech Festa on September 13-15 and will serve as a blueprint for other manufacturing companies to adopt Additive Manufacturing as a complementary manufacturing technology.

Source:Materialise

More information:

On Materialise’s official website.

SpaceX launches 3D-printed part to space, creates printed engine chamber

SpaceX launches 3D-printed part to space, creates printed engine chamber

Materialise Build Processor is the de facto standard for simplifying the 3D printing process

Materialise Build Processor is the de facto standard for simplifying the 3D printing process

Ultimaker Helps Master New Desktop Roles for 3D Printing at SOLIDWORKS World

Ultimaker Helps Master New Desktop Roles for 3D Printing at SOLIDWORKS World

Additive impact part #1 – how Additive Manufacturing could disrupt your market

Additive impact part #1 – how Additive Manufacturing could disrupt your market