Today, parts cleaning mostly means to fulfil defined cleanliness specifications. In order to clean as economically as possible, the potential of the cleaning system needs to be fully exploited. This is often prevented by the cleaning container. With the MEFO-BOX system, Metallform has developed a solution whose well thought-out design offers key advantages.

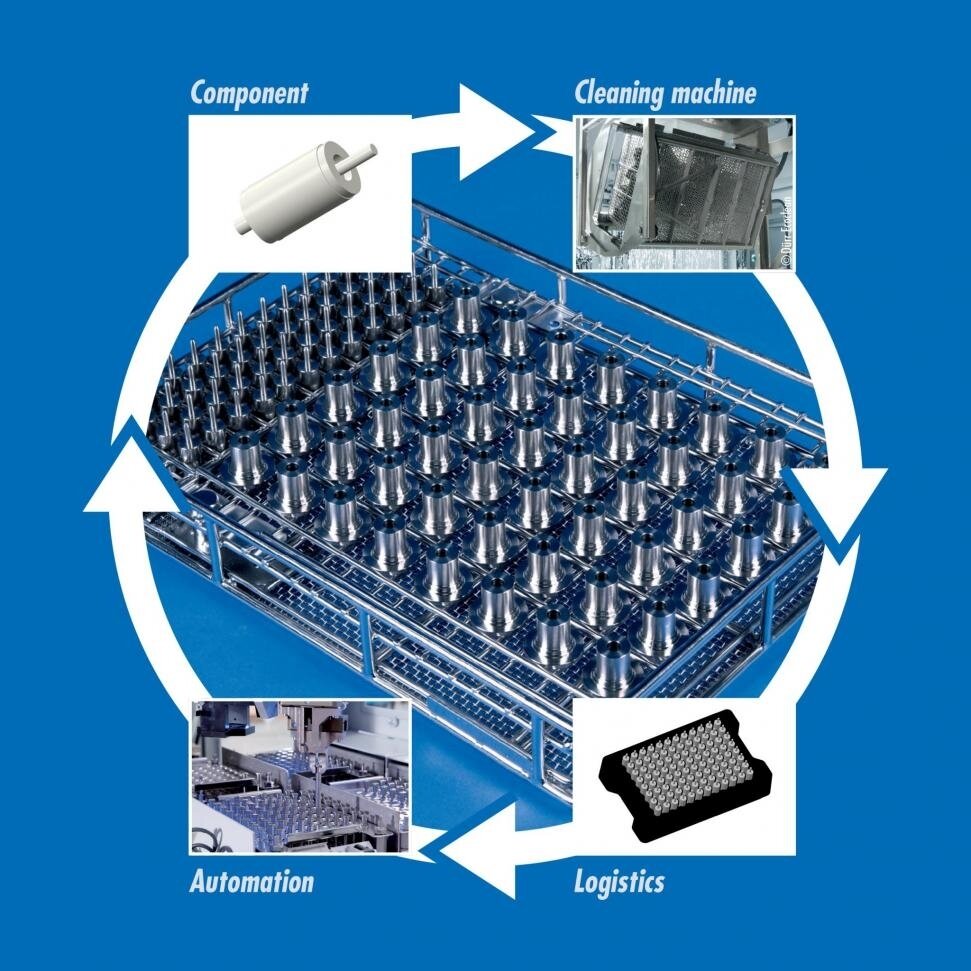

The cleaning basket is the link between parts and cleaning machine as well as logistics and automation. It therefore decisively influences efficiency and effectiveness of parts cleaning. Source: Metallform Wächter GmbH

When designing or optimising a cleaning process, much attention is usually spent on finding the appropriate machine, cleaning mechanics and agent. With this approach, it is frequently forgotten that the costly cleaning mechanics such as ultrasonic waves or spray jet as well as the cleaning media can only take their cleaning effect if they reach the parts to be cleaned. This is it what the MEFO-BOX system with standard cleaning baskets and accessories is designed for.

Faster, better and more efficient cleaning

Thanks to the system’s well thought-out design, open structure and its manufacture from stainless steels rounds with electrolytic polished surfaces, it ensures that the capability of the cleaning mechanics will be used at its best. Cleaning media as well as ultrasonic waves and/or spray jet have boundless access to parts and can take maximum effect. This yields to shorter cleaning processes with better results. Additionally, the easy accessibility of parts and good draining behaviour reduce the drying time required and enable uniformly dry parts – even in bulk material processes. Thus, the MEFO-BOX system enables increase in throughput without additional investments.

At the same time, the manufacture from rounds without closed edges and corners prevents the formation of dirt traps and residues in the container. As a result, process reliability is increased since re-contamination of parts is largely eliminated. The open basket design also minimises the carry-over of cleaning media, resulting in extended bath service life and thus improved system availability. Additional benefits of the MEFO-BOX system are compatibility to standard transport containers, a high stacking frame for safe transport and reliable separation as well as the integrated occupational safety due to completely welded joints without sharp edges, corners or wire ends.

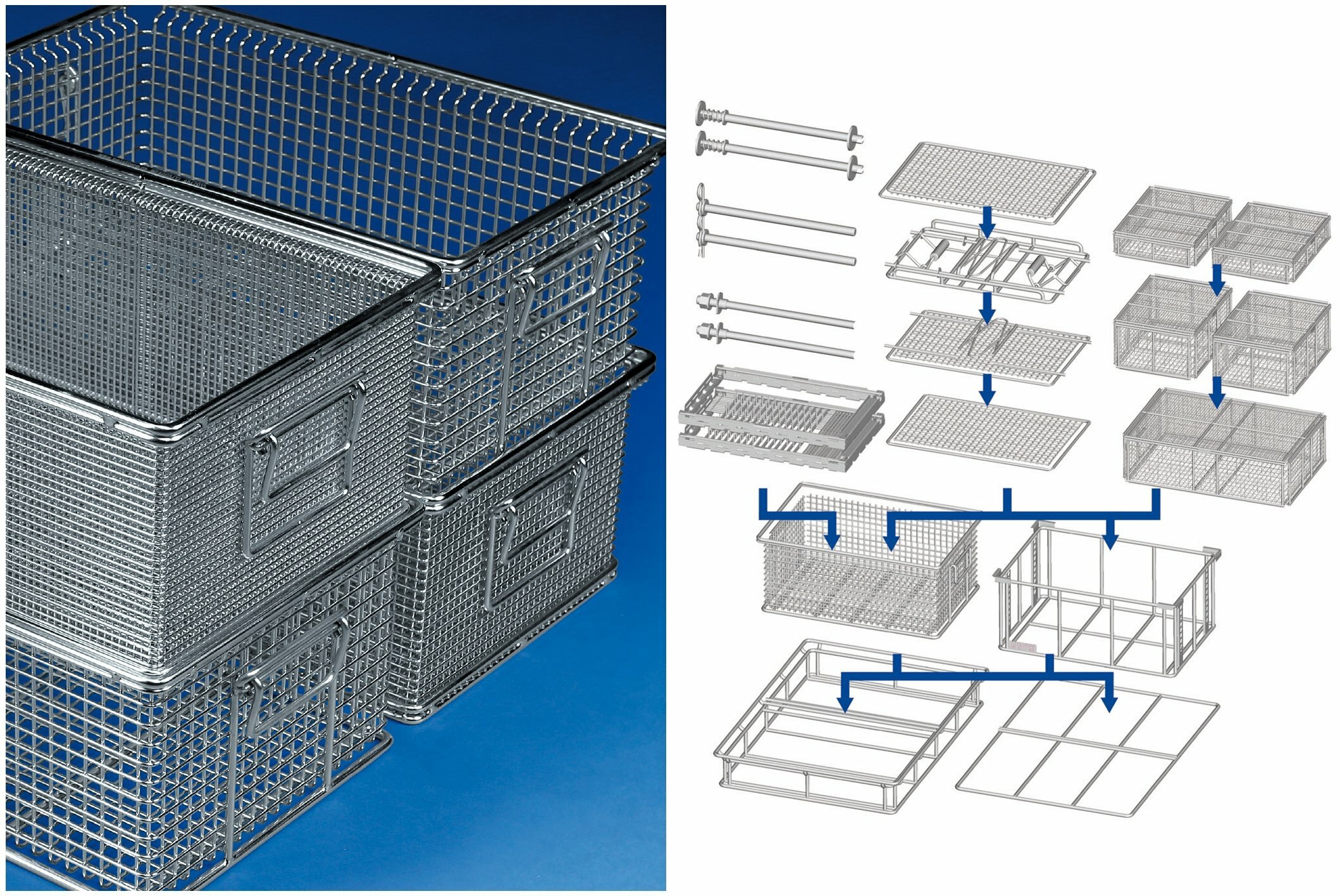

The MEFO-BOX system with standard cleaning baskets and accessories are designed for increasing efficiency and quality in cleaning processes. Source: Metallform Wächter GmbH

A system for countless applications

The extensive range of standard components of the MEFO-BOX system and of the flexible workpiece holder system MEFO-VARIO – both available ex-stock – allow to fix approximately 85% of all parts in the cleaning basket for the cleaning process. If required, the MEFO-BOX standard components can be supplemented by part specific components. This kind of a flexible solution is suitable for parts which are manufactured in small numbers, which have simple geometries as well as if the throughput is uncritical and no upstream or downstream handling has to be considered. Another application for such a solution is a frequently changing range of parts. A solution with standard components is also useful to gain experience with the cleaning process and handling of baskets and then optimise the system for all top seller parts in a second step.

For all other applications in which parts with complex geometries and/or large quantities have to be cleaned, Metallform offers a technically and economically optimised solution with part specific workpiece holders. This is also the case when the workpiece holders have to be automatically loaded and/or unloaded, designed for maximum throughput or adapted to a packing (e.g. blister pack).

Source:Metallform Wächter GmbH

More information:

On Metallform Wächter GmbH’s official website

How to optimize parts cleaning processes and cut costs

How to optimize parts cleaning processes and cut costs

Turning slender components made more secure

Turning slender components made more secure

Maximise turning productivity and output

Maximise turning productivity and output

Hexagon Launches Online Shop for Manufacturers in EMEA

Hexagon Launches Online Shop for Manufacturers in EMEA