The role of machining software in manufacturing has only grown more important as parts have grown more complex and EDM machine tools have become more capable.

Unfortunately, alongside this growth in capability there has been a growth in costly third-party software. The price tag of an average $10,000 CAM system can scare some shops, but for many others the additional $1,000 training and $1,000 annual maintenance contract costs are non-starters. This dilemma is the basis for part one of Sodick’s multipart series, “Why Pay More?”

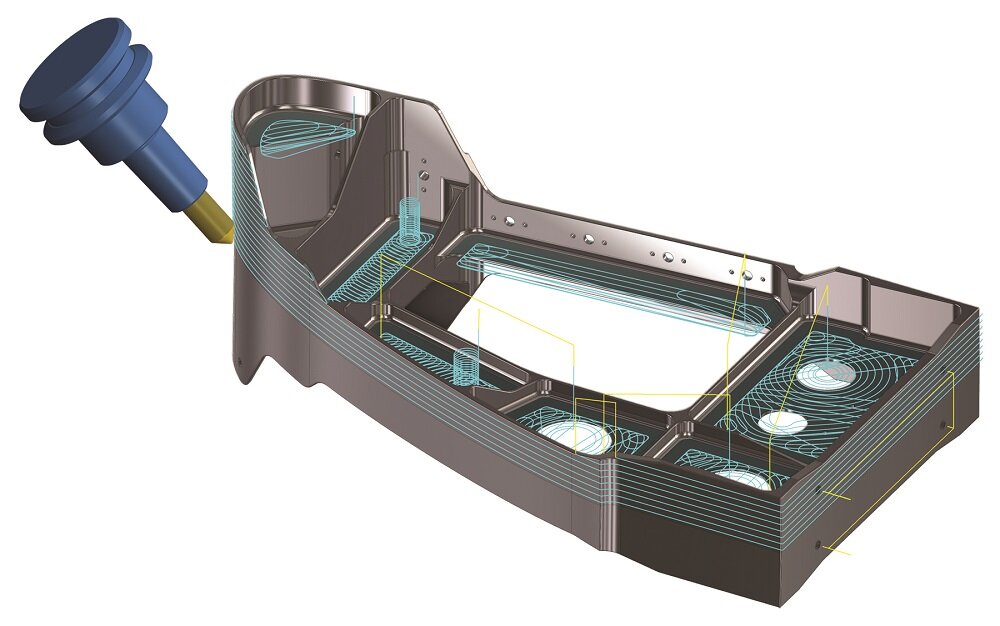

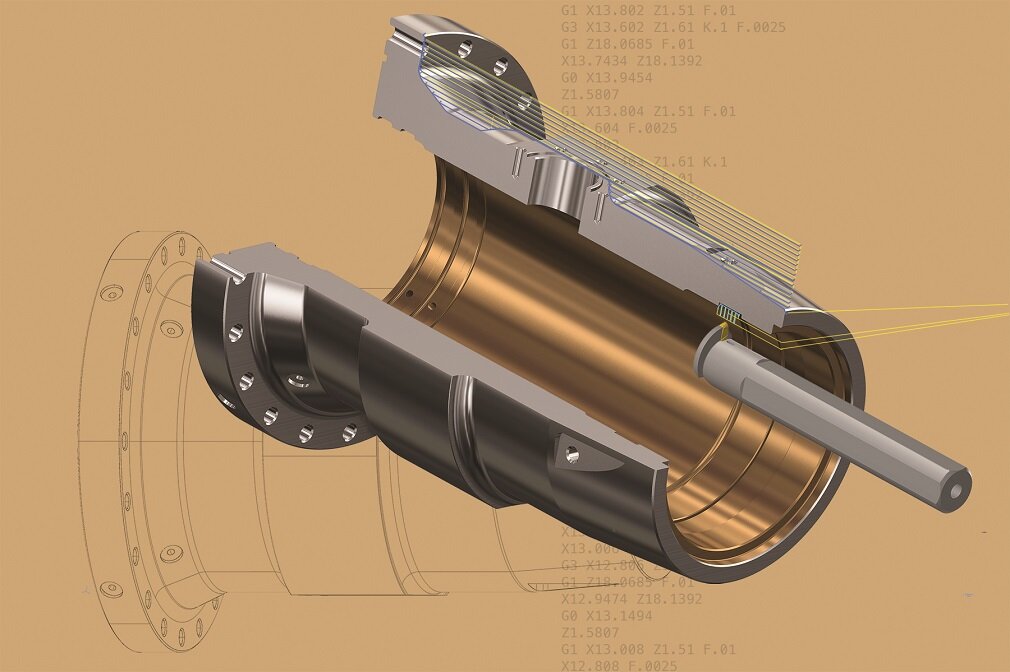

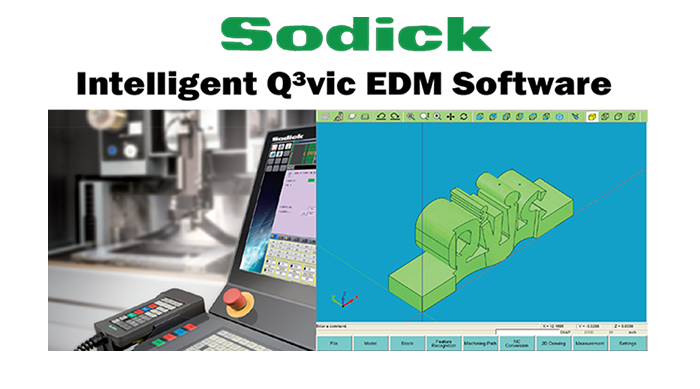

For shops requiring specialized or unique capabilities, or who have programmers well-versed in particular CAM softwares, the investment may make sense. But for the majority of general engineering facilities, software needs can be much less demanding. That’s why modern Wire EDM controls often offer the most in-demand capabilities, such as 3D CAD model import, feature recognition, and four-axis machining for particularly challenging medical and aerospace parts. For Sodick this means the “Intelligent Q3vic” software package that comes installed on Smart Pulse Wire (SPW) controls. Before adding the cost of specialty third-party vendors, EDM users should explore whether or not their standard software capabilities are sufficient, as features such as Intelligent Q3vic become more common on standard controls. If users are able to create programs by simply uploading a CAD model and selecting the desired cutting technology, then much of the programming leg work can be completed with the automatic detection of start holes and pockets. This means that a high level of efficiency can be achieved without the bloat of added software expense and yearly maintenance contracts.

For shops requiring specialized or unique capabilities, or who have programmers well-versed in particular CAM softwares, the investment may make sense. But for the majority of general engineering facilities, software needs can be much less demanding. That’s why modern Wire EDM controls often offer the most in-demand capabilities, such as 3D CAD model import, feature recognition, and four-axis machining for particularly challenging medical and aerospace parts. For Sodick this means the “Intelligent Q3vic” software package that comes installed on Smart Pulse Wire (SPW) controls. Before adding the cost of specialty third-party vendors, EDM users should explore whether or not their standard software capabilities are sufficient, as features such as Intelligent Q3vic become more common on standard controls. If users are able to create programs by simply uploading a CAD model and selecting the desired cutting technology, then much of the programming leg work can be completed with the automatic detection of start holes and pockets. This means that a high level of efficiency can be achieved without the bloat of added software expense and yearly maintenance contracts.

Source:Sodic

Ceramics: EDM Necessity, Not Luxury

Ceramics: EDM Necessity, Not Luxury

Edgecam Workflow in 2015 R1

Edgecam Workflow in 2015 R1

hyperMILL®: Perfection down to the smallest detail

hyperMILL®: Perfection down to the smallest detail

CREAFORM LAUNCHES VXREMOTE

CREAFORM LAUNCHES VXREMOTE

Edgecam Waveform Plays Key Role In Two Product Launches For Fenn Tool

Edgecam Waveform Plays Key Role In Two Product Launches For Fenn Tool