With the spread of new technological solutions the question is not whether we (our an external partner) can manufacture the product but rather how quickly and efficiently we can do it. The RapidDirect team is committed to reforming the way they are produced using a unique business model, whether it is for single or small-series production.

With the spread of new technological solutions the question is not whether we (our an external partner) can manufacture the product but rather how quickly and efficiently we can do it. The RapidDirect team is committed to reforming the way they are produced using a unique business model, whether it is for single or small-series production.

From rapid prototyping to serial production

The online service of China-based RapidDirect offers nothing less than manufacturing and shipping up to 24 hours of designed parts. Services include rapid prototyping, 3D printing, CNC machining, sheet metal working and injection molding. And with the listed procedures they can serve a wide range of customers with high quality and short deadlines.

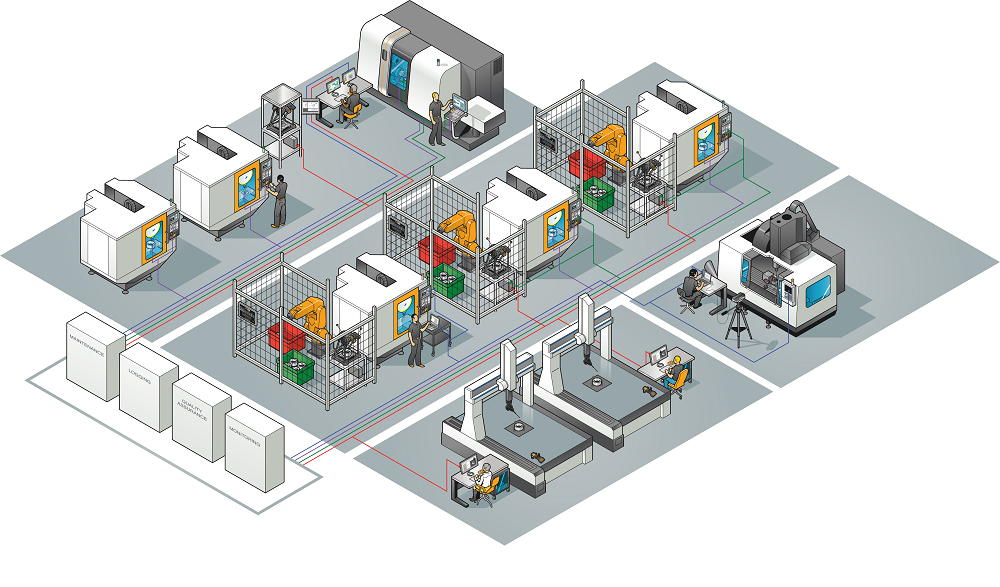

However, besides the completeness of te service, the real novelty is the online interface through orders are taken and managed, and the business solution the founders are thinking of. RapidDirect has a progressive engineering team relying on modern units with 150 highly qualified employees and a nearly 20.000 m2 workshop. This is where the ordered parts which can later be used and installed in many parts of the world are produced up to in large series.

This type of contract production offers an alternative solution in situations where the customer does not have production capacity or there is not available the appropriate technology. RapidDirect offers solution for this with its wide range and quantity of machining centers and with continuous availability.

Reality from model

The company takes over all steps of manufacturing process from the customer who has the only task of uploading the model of the part to be ordered. Through the online ordering interface the customer also receives a preliminary price calculation and a technology plan to, he can decide based on this documentation to finalize the order. Processing will begin at RapidDirect workshop after it happens and after preparation they manufacture the component by the appropriate procedure.

The way of production from 3D model to real part is determined by a special algorithm based on the initial data. Technology planning can be completed in minutes by using artificial intelligence – ordered parts can be produced quickly and in a cost-effective way.

Artificial intelligence is supported by the team consists of 150 engineers – they also help for customers in case of questions regarding material selection and technology. Geographical distance is no longer an obstacle in 2019: besides the online ordering interface the team also focuses on customer communication.

Established network of contacts to ensure efficiency

RapidDirect’s goal is to serve its customers to the highest standard, also including short deadlines. They can guarantee this by utilizing the spare capacity of partner companies in addition to their own production capacity – so they take large-series orders every day.

The well established manufacturing network, the online ordering system and technology process based on artificial intelligence is also an aspiration for the future. Founders of RapidDirect would fulfill the modern manufacturing demands by modern solution that ensures part manufacturing make faster, more efficient, and also cheaper, and more profitable for providers. This create an opportunity for the designed products to become a reality anywhere in the world, as well as an original idea as a prototype.

SourceRapidDirect